Contact us

Contact us

laser printer

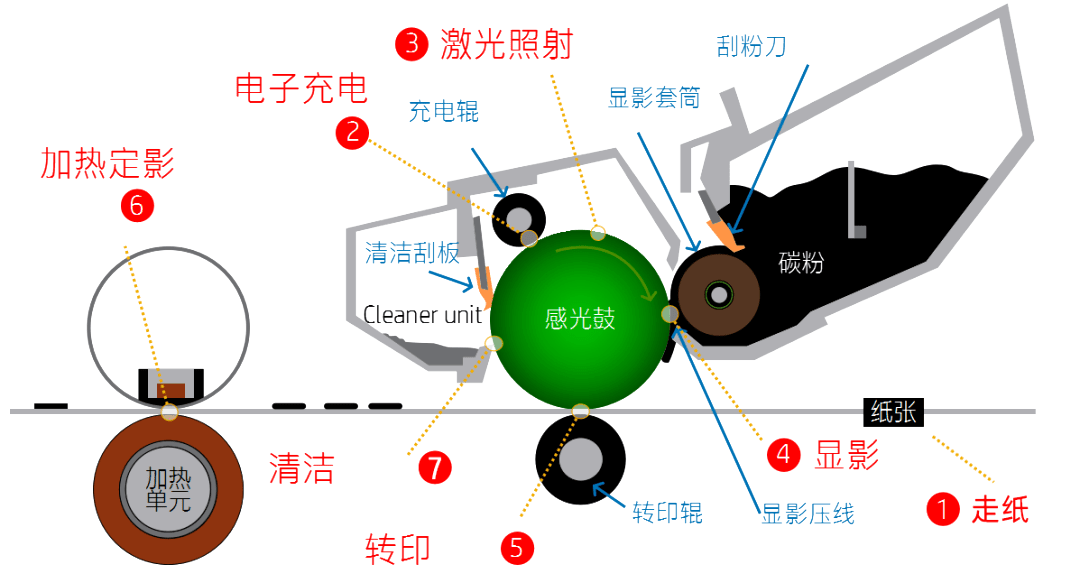

The printer's pickup wheel sends paper onto the paper path, and other devices ensure that the paper moves normally in the paper path, allow the paper to be accurately transferred and finally fixed.

When the printer receives a print job, it charges the charging roller shaft in the toner cartridge. After the charging roller comes into contact with the photosensitive drum, it removes the residual charge attached to the surface of the photosensitive drum and uniformly charges the surface of the photosensitive drum with a negative charge.

When the printer receives a print job, the laser emitter will emit laser light to illuminate the photosensitive drum. The illuminated part of the photosensitive drum surface will become a conductor, and the accompanying negative charge will be guided away, carrying a positive charge and forming a latent image of the printed content.

The developer roller absorbs the toner in the toner bin, and the developer blade evenly smears the toner on the developer roller into a thin layer. HP original toner is negatively charged. As the developer roller and photosensitive drum rotate, the negatively charged toner is adsorbed to the positive-charged latent image position on the photosensitive drum. (Opposite charges attract each other)

In the toner cartridge, the transfer roller carries a positive charge. When the paper passes through the transfer roller and is pressed by the transfer roller, it will carry a strong positive charge and absorb the negatively charged carbon powder on the photosensitive drum to form a real image.

The toner on the paper is heated and melted by the heating component, and is fixed on the paper through the resin in the toner, making the toner more firmly fixed and difficult to fall off.

After printing is completed, residual toner and charge on the photosensitive drum will clean the photosensitive drum to avoid affecting the next printing.